Assembly line

Assembly lineBrochure

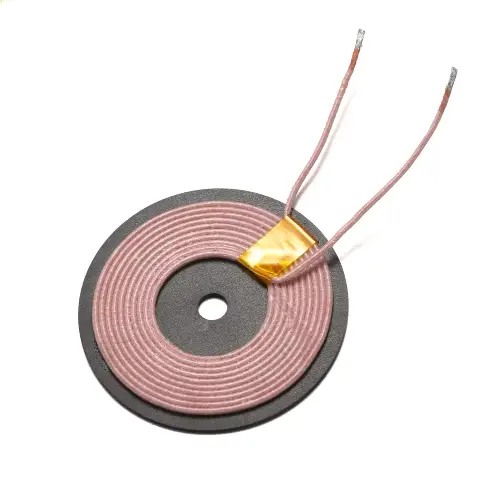

An assembly line is a highly efficient manufacturing system where a product is built step by step as it moves through different workstations. Each station is dedicated to a specific task, ensuring streamlined production, reduced lead time, and consistent quality.

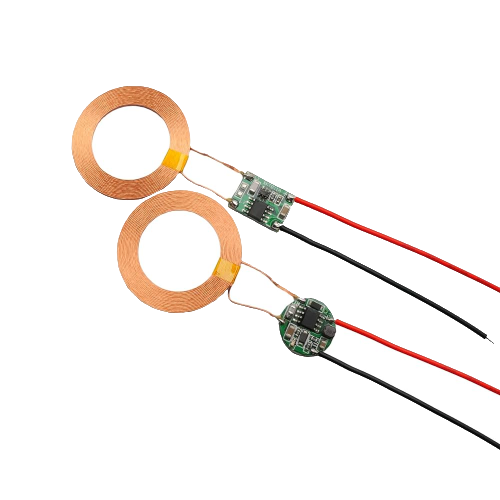

At our facility, we use advanced assembly line setups designed for precision, speed, and reliability. Whether it’s automotive components, electronic devices, or industrial equipment, our assembly lines are tailored to handle both high-volume production and specialized assembly requirements. With skilled technicians and automated solutions, we ensure accuracy, cost-effectiveness, and on-time delivery of every product.

Why Choose Assembly Line

Our assembly lines are designed for efficiency, precision, and scalability. By streamlining processes and reducing manual errors, we ensure faster turnaround times, consistent product quality, and the flexibility to handle complex electronic assemblies.

What is an assembly line?

An assembly line is a manufacturing process where a product is assembled in sequential steps across multiple workstations to improve efficiency and productivity.

What are the benefits of an assembly line?

It reduces production time, lowers costs, ensures consistency, and allows large-scale manufacturing of complex products.

Can assembly lines be customized?

Yes, assembly lines can be designed and adapted based on the type of product, production volume, and specific industry requirements.

What industries use assembly lines?

Assembly lines are widely used in automotive, electronics, appliances, consumer goods, and heavy machinery manufacturing.

Why choose us for assembly line solutions?

We provide modern, efficient, and flexible assembly line setups backed by expert supervision, ensuring high-quality output and optimized production processes.