Stamping

StampingBrochure

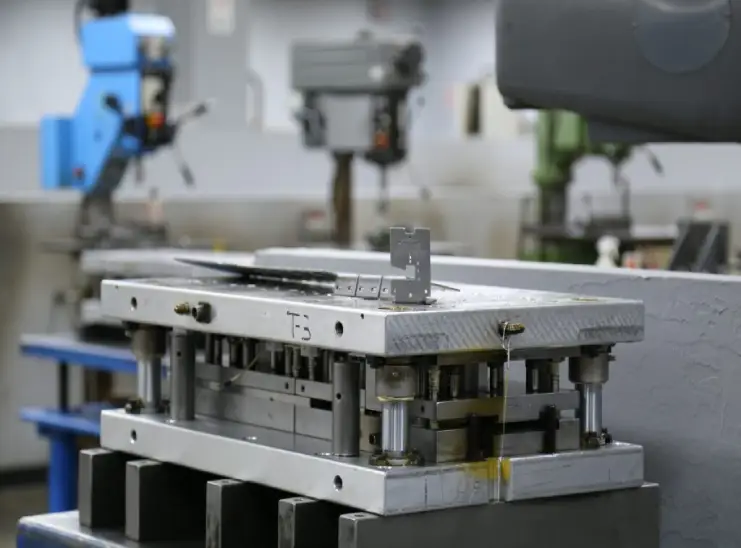

Stamping is a widely used manufacturing process that shapes and forms sheet metal into precise components through the use of specialized dies and presses. It is a cost-effective, high-speed method for producing large volumes of parts with consistent quality and accuracy.

At our facility, we use advanced stamping presses and durable tooling to manufacture components that meet strict international standards. Whether it’s simple flat parts or intricate designs with complex bends, our stamping solutions provide exceptional precision, strength, and repeatability.

This process is ideal for industries such as automotive, electronics, appliances, and industrial equipment, where large-scale production and consistency are essential.

Why Choose Stamping

Stamping is a fast and cost-effective method for producing high-precision metal parts in large volumes. It delivers consistent shapes and tolerances, supports complex geometries, and ensures strength and durability — ideal for electronic, automotive, and industrial components.

What is stamping used for?

Stamping is used to form and shape sheet metal into components such as brackets, panels, enclosures, and connectors, commonly used across automotive, electronics, and industrial sectors.

What are the benefits of stamping?

It offers high efficiency, excellent precision, lower production costs, and the ability to produce both simple and complex parts in large quantities.

Can stamping handle custom designs?

Yes, stamping can produce highly customized parts by using tailored dies and tooling, making it suitable for unique shapes and intricate designs.

What types of stamping processes are available?

Common types include blanking, punching, bending, embossing, and coining—each designed to achieve specific shapes and finishes.

Why choose us for stamping services?

We provide advanced stamping solutions backed by modern equipment, skilled professionals, and strict quality checks to ensure durable, accurate, and cost-effective components for every application.